When you need Durability, Versatility, Designerbility, Quality & Simplicity in floor matting product solutions you will find it all wrapped up in our Suremat range. Sure Mats from Matsdirect UK won't let you down!

We design, manufacture and supply a whole range of standard & bespoke specialist floor matting product solutions for all kinds of commercial, retail, industrial, leisure, hospitaliy, educational and governmental premises with products that also include safety mats, product launch avertising mats, POS counter mats and event VIP printed carpets.

Unsure of what you want is possible then talk to one of our experts now!

Simply phone us on +44 (0)161 797 6785 or e-mail sales@matsdirect.co.uk to get your mat requirement questions answered whilst also recieving personalised product pricing for your next matting project.

MatsDirect UK Limited is an ISO 9001:2015 QMS Accredited company. Making us your perfect partner for guaranteed high quality cost effective floor matting solutions with excellent customer service.

Learn more about MatsDirect UK Limited and see how you can benefit from our knowledge base and the Sure mat product range built up during 25 successful years.

MatsDirect UK Ltd are fully accredited for the ISO 9001:2015 (Quality Management System) standard which demonstrates our ability to consistently provide our products and services that meet our customer's applicable statutory and regulatory requirements.

ISO 9001:2015 also aims to enhance customer satisfaction through the effective application of the system including processes for improvement.

We provide our ranges of high-quality Sure mats rubber matting and PVC mat solutions to a wide range of customers that come from all corners of the world. We've been trusted by some of the world's most successful organisations to deliver high quality products from our sure mats range and still maintaining a competitive price edge along with proffesional advice on what works best for their needs. Some of our growing customer base includes:

Join the growing list and enjoy all the benefits they enjoy, from being a Matsdirect customer? ...the choice matters

The knowledge and expertise given in guiding us to the correct product for our needs was excellent and the Suretred star pattern Rubber matting product is doing a perfect job. Thank you Matsdirect.

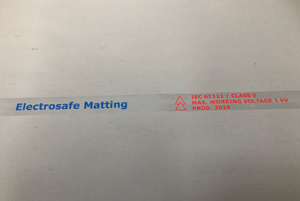

We have been purchasing various Electrosafe matting products from Matsdirect for over 10 years for our customers because we can rely on the quality, personal service, required certification and price points offering us the reliable supplier we need for our customers demand for the safety of their personnel.

The Logo mats supplied by Matsdirect in the UK have really emphasised the pride of the whole squadron in the serving of the American people.

The quality of the mats supplied by Matsdirect for each individual carriage of the whole train created the perfect image for our passengers at the start of their special journey on the most luxurious train in the world.

The fabulous printed carpet supplied by Matsdirect for our Christmas market was the finishing touch in helping to create a special place for our customers to enjoy their shopping at the end of this trying year.

We have been purchasing the Surewalk Matrix entrance matting system for 1 of our clients who would not now use any other product since first having it installed over 15 years ago in some 22 entrances and we have recommended it to other sites that we look after.

Thank you so much for the work you have done on this order. The new logo mats have arrived and they look great!!!

Thank you very much for your help with the entrance mat on the Sheffield store. It looks great. Steve the fitter was very helpful too and made sure the installation was perfect.

Thanks again and see you next time we need a mat.

Surewalk Diamond matwell entrance matting system Revolving Door

Surewalk Matrix matwell entrance matting system Shopping centre

Surewalk Diamond matwell entrance matting system with tagging machines

Surewalk Stratos matwell entrance matting system Retail Store

Surewalk Thrugaurd matwell entrance matting system Coir infils

Surewalk Matrix matwell entrance matting system with Corpromat

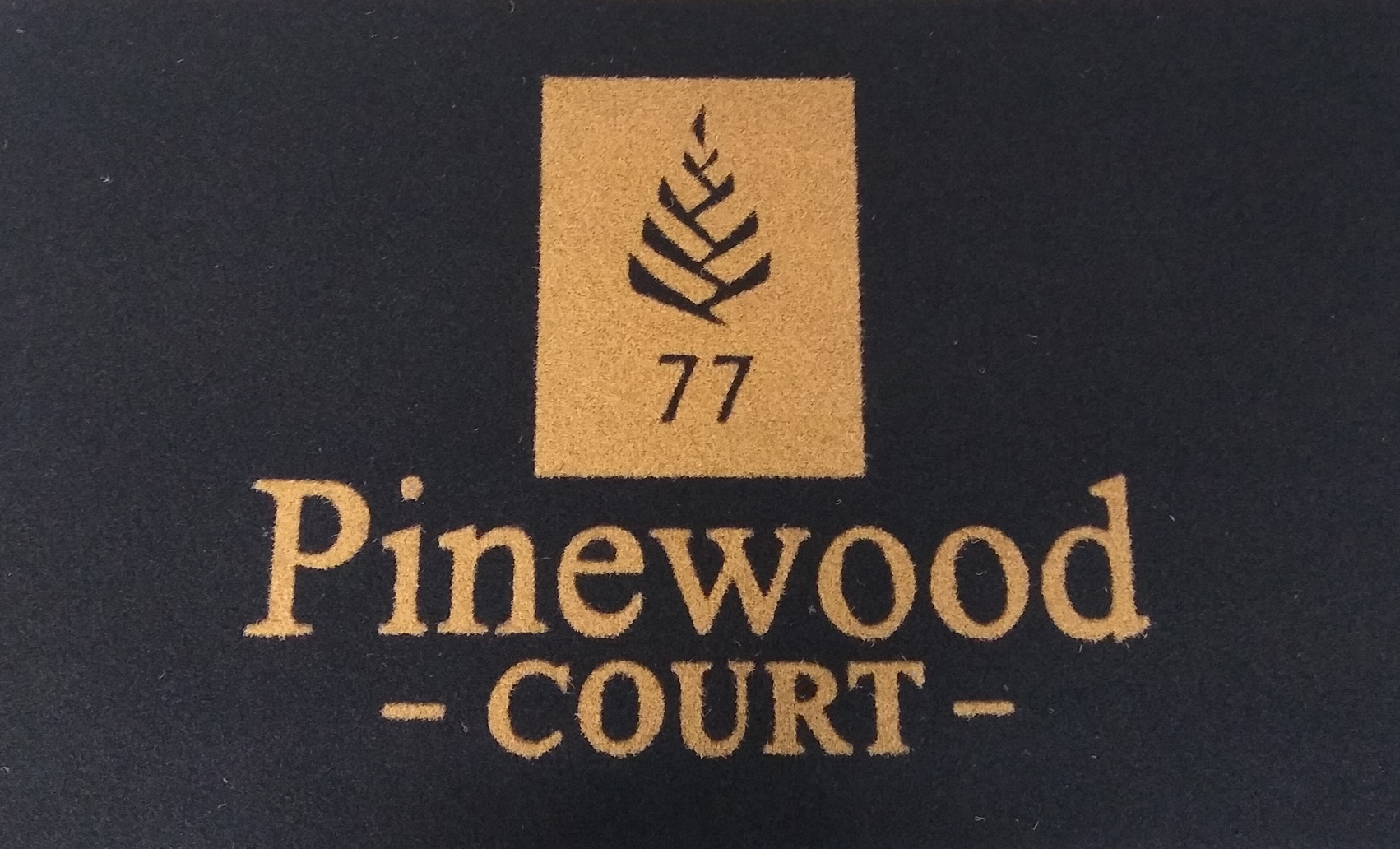

Main entrance matwell fitted with our Sureimage logo mat in Natural Coir

Main entrance area fitted with our Sureimage Coirsyn logo floor mat

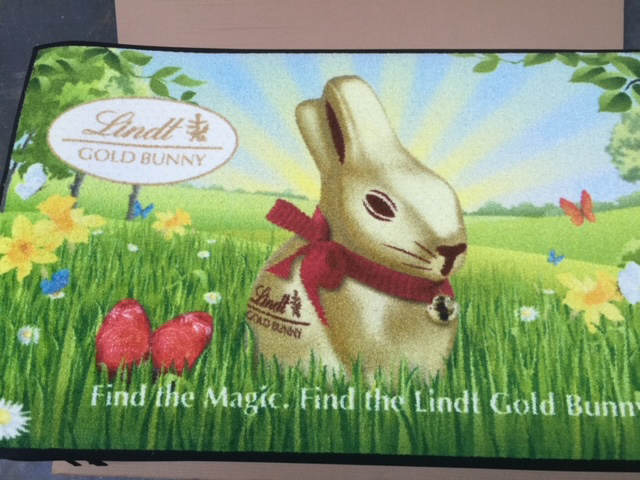

Part of the Lindt easter bunny campaign, placed in retail stores using our Sureprint option POS/POP logo mat product.

Sponsored football events by the Premier League and BP to promote the game using our Sureprint Prime Logo floor Mats.

Round Sureprint logo floor mat with lay flat Rubber border safety edge to prevent trips.

Promoting safety on any site is very important so Shell sent 75 Sureprint Prime logo floor mats to it's oil sites in Nigeria.

Round, oblong, square any shape of logo floor mats promote inclusivity and fun for learning in any school entrance environment.

The Amex brand promotional mats used in it's annual advert for the shop small small business saturday campagn.

Excellent Sureprint floor logo mats designed for short term promotions.

When it comes to brand promotion nothhing beats the impact of a full colour Sureprint image carpet.

Going to exhibitions with all the banners and promotional goods is a great way to promote your brand but a Sureprint logo floor mat really welcomes your visitors better than anything else.

Selfridges had a new logo for the Christmas promotion and a real eye catcher is was. So is the quality of our Sureprint image carpet.

When Taylor Made wanted to launch their new Golf club in 5 countries throughout Europe in two thousand outlets they needed a company that could not only print a quality Brand mat but box them individually and label them with the correct language and ship them to the correct countries to a dedicated launch date.

MatsDirect UK were the perfect partner to achieve this with our Sureprint Media Mats and our dedicated staff.

Website designed by Highpoint Media